Future of AI in Finite Element Analysis: A New Era of Simulation Intelligence

As industries push the boundaries of design, simulation, and optimization, the convergence of artificial intelligence (AI) and finite element analysis (FEA) is reshaping the engineering landscape. Once a purely numerical domain, finite element analysis is now being reimagined through the lens of machine learning, deep learning, and intelligent automation.

This article explores how AI is transforming FEA workflows, accelerating computation, and redefining the role of engineers in simulation-driven design.

? Why Finite Element Analysis Needs AI

Finite element analysis has long been the backbone of structural, thermal, and fluid simulations. However, traditional FEA methods face several limitations:

- High computational cost for nonlinear and multiphysics problems

- Time-intensive meshing and preprocessing

- Expert-dependent interpretation of complex results

- Limited adaptability to real-time design changes

AI offers solutions to these bottlenecks by introducing predictive modeling, automation, and intelligent decision-making into the FEA pipeline.

? AI-Powered Enhancements in FEA

The integration of AI into finite element analysis is not just theoretical—it’s already underway. Here’s how:

1. Surrogate Modeling

AI algorithms can learn from high-fidelity simulations to create fast, approximate models that predict system behavior with minimal computation. This is especially useful in design optimization and sensitivity analysis.

2. Automated Mesh Generation

Deep learning models are being trained to generate optimal meshes based on geometry and boundary conditions, reducing manual effort and improving accuracy.

3. Real-Time Simulation Feedback

AI enables adaptive simulations that respond to changing inputs during runtime, allowing engineers to explore design variations instantly.

4. Data-Driven Material Modeling

Machine learning is revolutionizing material behavior prediction by learning from experimental datasets, enabling more accurate and customizable constitutive models.

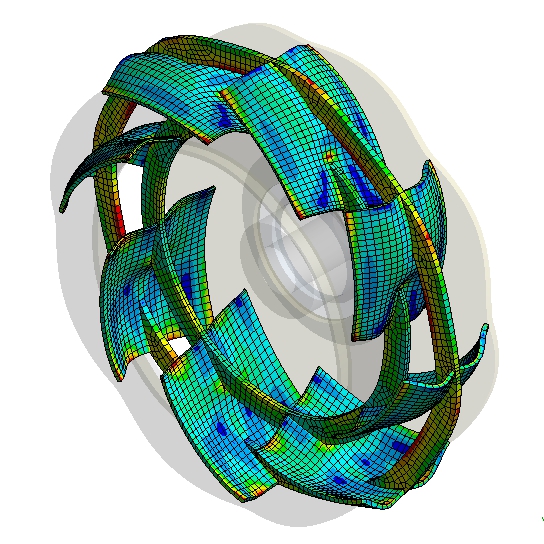

5. Intelligent Post-Processing

AI tools can automatically detect anomalies, classify failure modes, and highlight critical regions in simulation results—saving time and improving decision-making.

? Case Studies and Industry Adoption

Leading simulation platforms like Abaqus, ANSYS, and COMSOL are already embedding AI modules to enhance their FEA capabilities. For example:

- Abaqus software is exploring Python-based machine learning integrations for custom material models and solver acceleration.

- Research published in 2024 highlights how ML techniques are being used to reduce FEA computation time and improve model generalization across domains like biomechanics, geomechanics, and aerospace.

? SEO Insight: Why “Finite Element Analysis” Is the Anchor

The keyword finite element analysis remains a high-value search term across engineering, academic, and industrial sectors. By aligning AI advancements with this core term, content creators and technical platforms can:

- Increase organic traffic from simulation professionals

- Establish authority in emerging engineering technologies

- Capture interest from AI researchers entering the FEA space

? What’s Next: AI-Driven FEA Ecosystems

The future of FEA lies in fully integrated ecosystems where AI:

- Designs the simulation

- Executes it with minimal human input

- Interprets results autonomously

- Feeds insights back into the design loop

This shift will redefine engineering roles—from manual analysts to strategic simulation architects.

? Final Thoughts

AI is not replacing finite element analysis—it’s amplifying it. As algorithms grow smarter and datasets richer, engineers will gain unprecedented simulation power. The fusion of AI and FEA marks the beginning of a new era: one where design, analysis, and innovation move at the speed of intelligence.